I am working to read two quadrature encoders using a single Arduino DUE, as part of my summer vacations project. According to the following link http://atmel.force.com/support/servlet/fileField?id=0BEG0000000HRvP, the SAM3X8E has 2 quadrature decoders in it. Now I am not being able to understand how can I initialize this second quadrature decoder. According to Quadrature Decoder QDEC for SAM3/4 Devices_ApplicationNote_AT11483 Pg16 we have to first configure the IOPINS for QDEC1. I have to do that same task in Arduino IDE instead of Atmel Studio.

This is the code that I have found and works well to read encoder using QDEC0. However, I now need to read the encoder using the second quadrature decoder, whose input pins are TIOA6 , TIOB6 which correspond to Pin 5 and 4 of Arduino DUE. After reading the Atmel SAM3X datasheet, I think I should change "TC0" with "TC2" to make the second decoder work. However, this doesn't work. I think it does not work because channel 2 is busy in time base calculations. In Application Note 5.52 QDEC Speed Measurement Mode point 2 says to Initialize TC0, TC1, TC2. If I wanted to used other encoder which timer instance will be used.

/*

** Quadrature Encoder on Arduino Due in "Speed Mode"

** Will not work on other Arduino types because of a specific hardware requirement.

**

** @bungle99 / 2014-02-28

**

** Many thanks to @Designservicecorp (notably post #32 and post #42) that gave me the base to work from.

**

** Uses *hardware* to do the heavy lifting of interpreting the Encoder output, which gives it significant

** advantage over other Arduino's for this use case. Eg many people have reported their Unos maxing out

** or skipping counts when interpretting high RPMs, whereas people using the Due in hardware mode have

** reported better success with high RPMs.

**

** This particular example puts the hardware into "Speed" mode, whereas other examples in this thread use

** "Position" mode (see posts 32, 42). The one example in the thread that attempts Speed calcs uses Position

** Mode and uses an interrupt on the Z Index axis to manually apply a time period (needed to caculate speed)

** on each rotation.

**

** This code below has been used in tests (using Lego NXT and a gear train for driving / comparison) to

** ~3,500 RPM with a 1,024 PPR Encoder (4 x 1,024 Edges). The Arduino didn't seem to struggle and the

** numbers (eg RPM) matched fairly closely with the Lego (eg as a sanity check, the calcs in the code look

** correct).

**

** I bought one of these encoders, which seems ok;

**

** * http://proto-pic.co.uk/rotary-encoder-1024-p-r-quadrature/

**

** Great service from proto-pic. The encoder specs are officially

**

** * http://dlnmh9ip6v2uc.cloudfront.net/datasheets/Robotics/E6B2Encoders.pdf

**

** But look an awful lot like this one too (which is easier to read)

**

** * http://www.ia.omron.com/product/item/e6b27032r/index.html

**

** Note that this Encoder is rated at 5V min. I've successully powered it off the 5V Arduino pin header,

** and it doesn't work off the 3.3V one. At 5V, the outputs need to be run through some resistors to bring

** them into tolerance of the Arduino inputs.

**

** The inputs are 2 and 13 (and optionally A6 for the index).

**

** The test hardware (some Lego NXT servos and gear train) was unable to turn any faster (more gears

** stalled the servos) - eg the Arduino Due was not the limiting factor. At this speed, the Due Hardware

** is dealing with approx 238,000 edges per second.

**

** This example offloads the speed calculation onto the hardware, meaning no interrupt is required.

** In addition, the index is not required either, so it allows speeds to be seen even for rotations that

** don't pass the index marker (for example, slow rotations needing a speed before a complete rotation).

** That said, index is available if you want it and the docs suggest you can still use it (and others) as

** interrupt if you wish.

**

** NB There appears to be a myriad of features on the Chip that have not been touched. Eg you can still add

** interrupts to this code to do other things; eg passing the Z index, direction changes. There are also

** filters available if your encoder suffers from noise (eg vibrations). All this is available to play with

** another day :)

**

** Code appears to work, but no guarantees. Understand it. Test it. Feedback to the group. YMMV. Don't blame

** me if it doesn't work or expolodes!

*/

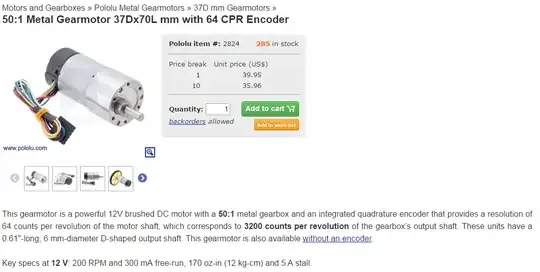

const int ENCODER_EDGES_PER_ROTATION = 3200; // this depends on your encoder

const int ENCODER_SAMPLES_PER_SECOND = 10; // this will need to be tuned depending on your use case...

const int LOOP_DELAY_MS = 1 * 1000; // ... as will this (see comments in main code)

void setup() {

Serial.begin(115200);

delay(10);

// Setup Quadrature Encoder

// http://www.atmel.com/Images/doc11057.pdf

// Section 37 p869

// Section 37.6.14 p885

// Section 37.6.14.2 p890 Position and Rotation Measurement

// Section 37.6.14.5 p891 Speed Measurement (what this is about)

REG_PMC_PCER0 = PMC_PCER0_PID27

| PMC_PCER0_PID28

| PMC_PCER0_PID29;

// Setup a channel in waveform mode (eg an input into the encoder to trigger the time based sampling)

// Note some of the choices here impact calculations below and if you change them, you need to change

// the next section to suit.

// Section 37.7.11 p906 (also refer to Section 37.6.14.5 p891 for detail of what to set)

REG_TC0_CMR2 = TC_CMR_TCCLKS_TIMER_CLOCK4

| TC_CMR_WAVE

| TC_CMR_ACPC_TOGGLE

| TC_CMR_WAVSEL_UP_RC;

// Now define the sample period, using the clock chosen above as the basis

// Note that REG_TC0_CMR2 above is using CLOCK4; this is an 128 divisor. You need to change the

// divisor below if you change the clock above. You could change the input clock and the RC mode to

// suit your app (eg how many pulses are you expecting - depends on encoder type

// and slowest/normal/fastest rotation speed and what you want to do with the result).

// Section 37.6.14.5 p891 notes you need to set this up, otherwise 0 comes out all the time :-)

REG_TC0_RC2 = F_CPU / 128 / ENCODER_SAMPLES_PER_SECOND;

// Setup a channel in capture mode

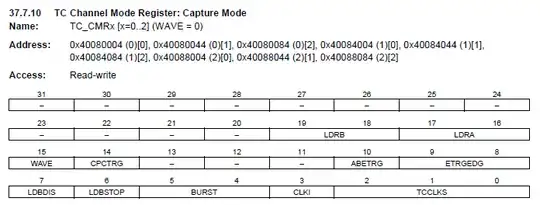

// Section 37.7.10 p904 (also refer to Section 37.6.14.5 p891 for detail of what to set)

REG_TC0_CMR0 = TC_CMR_ABETRG

| TC_CMR_LDRA_EDGE

| TC_CMR_LDRB_EDGE

| TC_CMR_ETRGEDG_EDGE

| TC_CMR_CPCTRG;

// Enable features, noting Speed not Position is chosen

// Section 37.7.2 p895 (also refer to Section 37.6.14.5 p891 for detail of what to set)

// 37.7.2 TC Block Mode Register

REG_TC0_BMR = TC_BMR_QDEN

| TC_BMR_SPEEDEN

| TC_BMR_EDGPHA; //Pg 896

/*EDGPHA: EDGe on PHA count mode

0: edges are detected on both PHA and PHB.

1: edges are detected on PHA only.*/

// Set everything going

REG_TC0_CCR0 = TC_CCR_CLKEN | TC_CCR_SWTRG;

REG_TC0_CCR1 = TC_CCR_CLKEN | TC_CCR_SWTRG;

REG_TC0_CCR2 = TC_CCR_CLKEN | TC_CCR_SWTRG;

}

void loop() {

int iIndexCount = REG_TC0_CV1; // Don't need this, but manual notes its available

int iSpeedPPP = REG_TC0_RA0; // This is what we're really after (speed in Pulses Per sample Period)

// which we can convert to rps or rpm easily

double dSpeedRPS = ((iSpeedPPP / (ENCODER_EDGES_PER_ROTATION * 1.0)) * ENCODER_SAMPLES_PER_SECOND);

double dSpeedRPM = dSpeedRPS * 60;

Serial.print("Speed ppp: ");

Serial.print(iSpeedPPP);

Serial.print(", ");

Serial.print("Speed rps: ");

Serial.print(dSpeedRPS);

Serial.print(", ");

Serial.print("Speed rpm: ");

Serial.print(dSpeedRPM);

Serial.print(", ");

Serial.print("Indexes: ");

Serial.print(iIndexCount);

Serial.print(". ");

Serial.println();

// Slow down the main loop noting the Encoder can update independently in the background (we're

// effectively polling it to find out the latest and greatest info on each loop around).

delay(LOOP_DELAY_MS);

}

Additionally I wanted to ask what is the difference between REG_TC0_CMR2 REG_TC0_CMR0 and REG_TC0_CMR1 ? Two of them are used in the above code.