I want to use hydraulic flow to proportionally vary the resistance of a rpi controlled exercise machine. The victim would rotate a positive displacement pump where the inlet and outlet ports are connected through one or more valves.

I would prefer to use a servo to vary the flow through a single valve. Integrated servo control valves on ebay are rather expensive. How practical would it be to attach a servo, say, to a plumbing shutoff valve?

Solenoid vales are cheap by comparison. I'm considering using only one as a pulse width modulator to vary the flow. I think it would need to be banged open and shut between 5-10 hz for a smooth flow. Would it likely hold up under that?

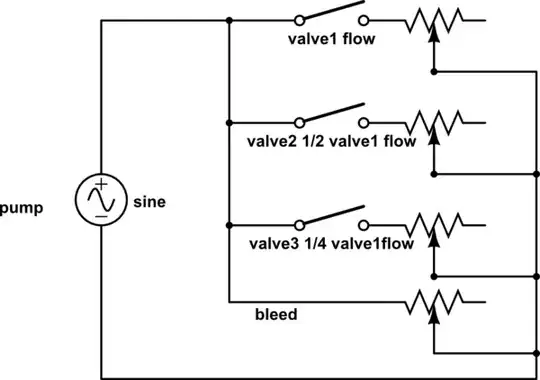

Alternatively, a couple could be ganged with harmonically arranged open flows between an outlet and an inlet manifold:

simulate this circuit – Schematic created using CircuitLab

Appreciate feedback/recommendations!