This sounds, to me, like a job for CAN. It's the current de-facto standard for industrial inter-MCU cabled connections. It's used, not only in automobiles, but also to control elevators and almost all other modern industrial distributed applications.

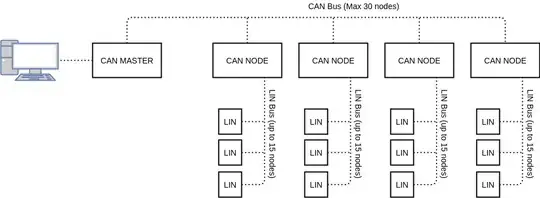

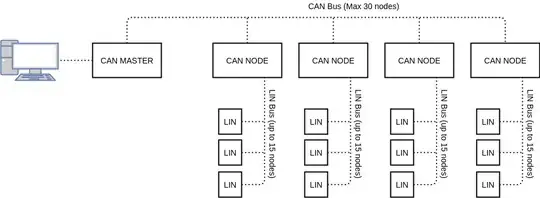

Note that CAN is designed to only support up to 30 nodes, so you would need to split your network into sections and have groups of nodes amalgamated together into a single sub-network. For 200 nodes you may want 10 subnetworks - that is, 20 nodes connected together to one super-node, which is then connected to the "backbone" CAN bus.

However, CAN can be run at lower baud rates than normal, and that increases the number of nodes you can have on any one network segment. It potentially (bus capacitance permitting) support thousands of nodes.

Another option is to use CAN to connect multiple "master" nodes together into a backbone, and then those "master" nodes connect to a number of sub-nodes using LIN (which is cheaper to implement than CAN).

LIN can support a maximum of 15 nodes (plus one master node) per network, so you can get a theoretical maximum of 29*15 (assuming 1 CAN node is the connection to the PC), or 435 nodes.

You could also use RS-485, but that is also limited to around 30 "unit loads", and the number of nodes you could put on one segment is dependent on the "load" each node imposes. In practical terms it's rare to go over 30-40 nodes on a single segment, and grouping nodes together into sub-networks (as above with CAN/LIN) would be needed. So you may as well use the current standard for this kind of communication, and use CAN/LIN.