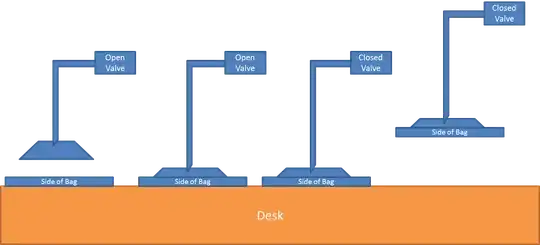

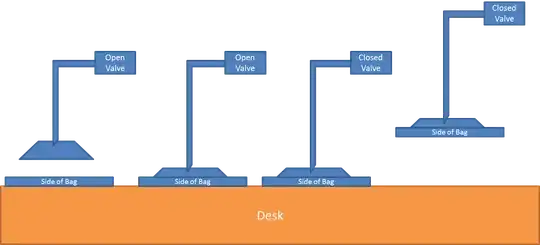

There are two approaches I can think of that would work decently. Either a.) suck air out of a "cup," turning off the pump when done. OR b.) have a valve where the arm pushes one part of the bag against the table to squeeze all the air out of it, and shutting a valve attached to the "cup." Then, to release, the valve could be opened. For the suction cup, I'd personally try making it out of a suction cup hanger like this:

Source: http://www.amazon.com/Set-Large-Suction-Hanger-Hook/dp/B00439SCZO

The availability of these might vary by area, so I'm not sure how common these are in the UK. If you find one, make sure that it's pretty thick, with not that large of diameter so it's not too big to work with. I'd then remove the metal hook with pliers and drill a hole in the center. After that, you would need to superglue a tube through the center of the hole and seal it with some caulk.

Like I mentioned earlier, the two options are to a.) suck to grab and turn off pump to release or b.) have arm apply pressure to a flat surface and then shut a valve attached to the tube, creating negative pressure in the suction cup. Then, you could open the valve to balance the pressure and let the item go. I'd personally do the suction approach because, although it is louder and might use a little more electricity, it's a bit easier to build and execute and can grab in the air. I'm going to focus on that.

For the pump approach, build the suction cup (like I said above), attach the tube to one end of the motor with a hose clamp, leave the other hose terminal unconnected, and connect the pump (through a relay) to a 12V 1A+ power supply. You can do this by connecting the + pin of the pump to the "out" (or similar) pin of a relay breakout board, the "in" (or similar) of the relay to the power supply +, and the - of the pump to the power supply's - wire. This will make a circuit similar identical to a switch (the switch being the relay). To connect the relay to the Arduino you will have to connect the relay's logic signal to a pin on the Arduino and then you can just write HIGH or LOW to turn the pump on and off.

EDIT: Forgot to mention, you can use a transistor, too. Also, I illustrated the second method (hopefully it makes this clear).